News

Space Sensorship

July 26, 2017

NYIT is heading to space. Or at least a device developed by a faculty member is.

Fang Li, Ph.D., assistant professor at NYIT School of Engineering and Computing Sciences, is working on an embedded sensor system for NASA that is capable of measuring temperature, pressure, and strain on various rocket propulsion engine components. “The device will be used to prevent imminent and catastrophic failures in rocket engines,” explained Li.

The technology is being developed with X-Wave Innovations, Inc. (XII), a research and development firm specializing in the defense, homeland security, transportation, and energy fields. The 12-month venture is part of a project funded by a $125,000 NASA Small Business Technology Transfer (STTR) Phase I grant.

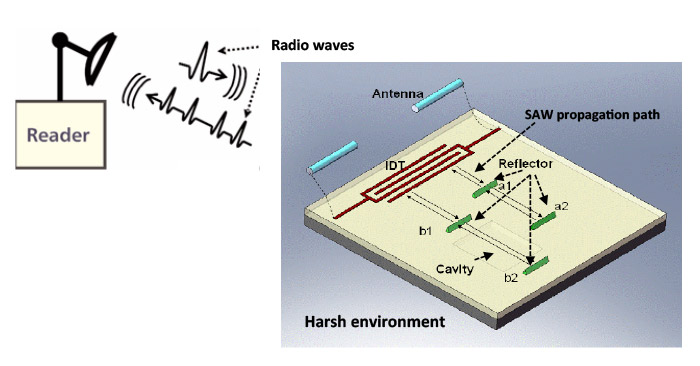

The innovative sensor will provide a highly flexible instrumentation solution to monitor remote or inaccessible measurement locations for NASA’s rocket propulsion test facilities. This sensor system is a hybrid product of passive Surface Acoustic Wave Radio Frequency Identification (SAW-RFID) technology and high-temperature piezoelectric materials and devices. (Piezoelectricity is the ability of certain materials, such as lithium niobate and aluminum nitride, to generate an electric charge when subjected to mechanical stress.)

The sensor system consists of sensor tags and a remote RF interrogation system. The sensor tags are embedded in measured components, powered by an incident RF signal which requires no power supply or external circuits. It remotely collects data from multiple sensors and converts data into values of temperature, pressure, and strain.

According to Li, conventional sensors pose challenges to engineers. For example, they are neither cost-effective nor do they provide a reliable assessment of the health of propulsion engine components in harsh, high-temperature environments. The technology being developed at NYIT may solve those problems. Sensor tags are embedded in measured components and powered by an RF signal that requires no power supply or external circuits. Because the sensors are passive, they are able to work in harsh environments inherent in space travel that would normally destroy conventional electronics.

“The sensor system can operate for long periods, maintenance-free, providing valuable data about the structural health and operation conditions of the engine components,” she explained.

Li is working with Jonathan Furniss and Abhay Dilip Patil, two NYIT mechanical engineering graduate students, to model, design, and develop passive SAW sensors at NYIT-Long Island in its class 10,000 clean room, which is part of the university’s materials science and microscopy lab.

“Our mission is to provide high quality education and support faculty research and student learning in high-tech focus areas,” said Nada Anid, Ph.D., dean of the School of Engineering and Computing Sciences. “This prestigious NASA grant is a perfect example of collaboration between our faculty and industry on important technological advances. It offers a tremendous growth opportunity for both Professor Li and her students.”

Li, Furniss, and Patil will create a prototype of an embedded sensor system with XII. Once the results demonstrate the feasibility of this technique, the team will apply for Phase II funding which will allow them to build the SAW-RFID system that will be used at the Stennis Space Center testing facilities. And then, perhaps, one day it will head to space.